Compression Packing Basics: Structure, Function and Application

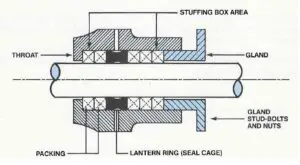

Compression packing is a sealing device in a mechanical equipment. It performs the sealing function, typically controlling fluid or gas leakage. Compression packing is usually made from relatively soft, pliant materials, consist of a number of rings which are inserted into the annular space -(stuffing box) between the rotating or reciprocating member, and the body of the pump or valve. (see Stuffing Box Diagram)

By tightening a follower or packing gland against the top ring, pressure is transmitted to the packing set, expanding the rings radially against the side of the stuffing

box and the reciprocating or rotating member, effecting a seal.

Compression packings find their major use in the process industries such as petro-chemical, paper and steel mills, and in the service industries like utilities, marine, water, sewage, food and nuclear. They seal all types of fluids including water, steam, acids, caustics, solvents, gases, oil, gasoline, and other chemicals over a broad range of temperature and pressure conditions. They are used in rotary, centrifugal, and reciprocating pumps, valves, expansion joints, soot blowers,

and many other types of mechanical equipment. Compression packings are relatively easy to install and maintain. With proper attention, a high degree of successful operation can be anticipated.

Successful sealing with compression packings is a function of several important related factors:

- Careful selection of packing materials to meet the specific application requirements.

- Complete consideration of surface speeds, pressures, temperatures, and medium

handled. - Proper attention to good installation and break-in procedures.

- High standards of equipment maintenance.

Compression packings used in pumps, whether in rotating or reciprocating service, normally depend on a fluid film between the surface of the moving member of the equipment, and the packing, for lubrication. Sources of this fluid film are built-in lubricants (liquid, solid, or in combination), leakage of the medium handled, or an external lubricant supply. On equipment start-up, lubricants may be released from the packings bygland pressure to provide initial lubrication and sealing. During the break-in period, these lubricants bridge the period between dry operation and the introduction of the normal lubricating system. Gradually, by adjustment of the gland pressure, the pumped medium, or the external lubricating source, takes over the lubricating function by providing a continuous source of fluid film. Gland pressure

is regulated to provide optimum lubrication to seal and prevent overheating and consequent damage to the shaft or rod. Built-in lubricants that are lost gradually during the operation of the equipment are compensated for by further gland adjustment. When the volume loss of lubricated packing approximates the original amount of built-in lubricant, the effectiveness of the packing is lost, and replacement is required. Built-in lubricants may also serve the important

function of blocking the passage of fluids being pumped, thus preventing excessive leakage. Compression packings used in valves where there is slow or infrequent motion, and those used in static operations, are required to seal without leakage. Various impregnants may be used to assist in this function. Some packings are designed with non-migrating stable lubricants for operation under extreme pressure and temperature.

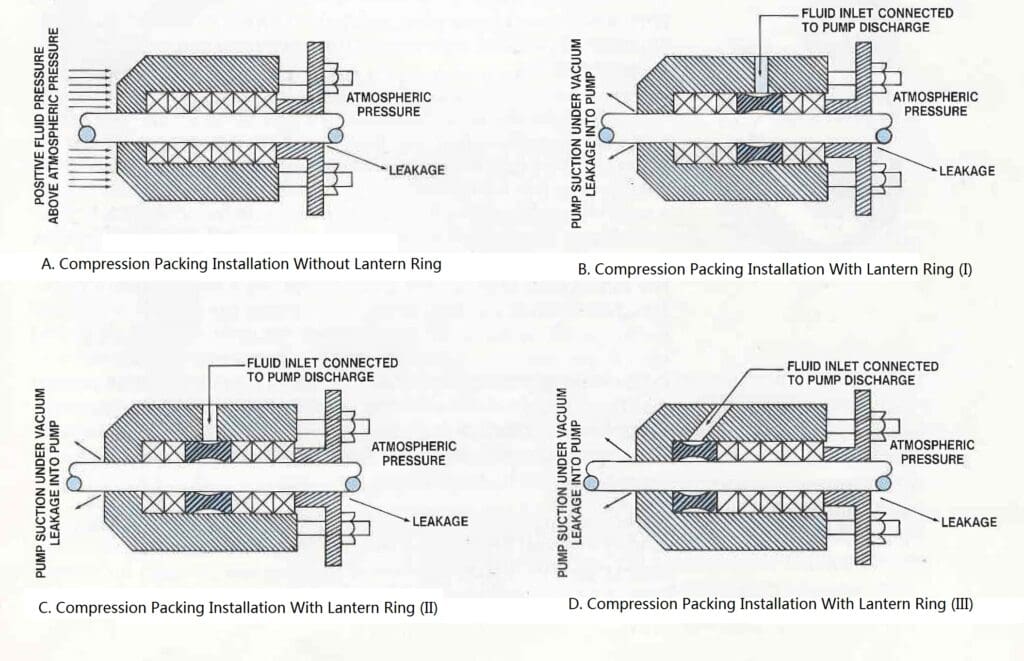

Depicted below are typical methods of the use of compression packings in pumps. Note the use of lantern rings (seal cages) where external means of lubrication are required.

Great information!

We are rebuilding the engine in an old 1961 V8 car and can no longer buy packing in the original size for the rear main bearing seal. Will Palmetto Flexible Graphite Compression Packing Seal work for our application? What do you think? I just need an opinion, not a guarantee.

Thanks!

Flexible graphite packing is right for the temperature and resistant to gasoline. So it might work. Our style GraficBraid 1000.