Six Relevant Physical Features of Ceramic Fiber Textiles

Ceramic fiber is a primary material used in various industries requiring refractory solutions. Well known as a versatile, heat resistant material, ceramic fiber has physical properties (low heat conductance, low thermal expansion, and high heat capacitance) that are expected of something used in heat management applications. An understanding of the refractory properties of ceramic fiber can be obtained by focusing on six physical features.

Aluminum Foil

Sand

1. Chemical Composition

Most ceramic fibers are made up of a 1:1 mixture of aluminum oxide (alumina) and silicon oxide (silica). Alumina (Al2O3) is a chemical compound of aluminum and oxygen, known to have high heat resistance. Silica (SiO2), most commonly found in nature as quartz, also has refractory properties. Combining these materials to make ceramic fiber also combines the heat resistance properties of both.

2. Fiber Diameter

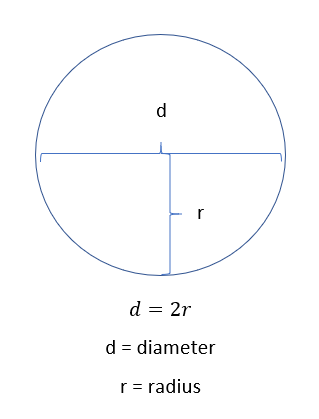

Another important feature of ceramic fiber textiles is the diameter of ceramic fibers. Diameter (of a circle) is defined as the length of a segment that passes from one part of the circle to another through its center. The equation above relates the diameter of a circle to its radius. The radius is the distance from any part of the circle to the center. The radius is always half the diameter. On average, the fiber diameter for ceramic fiber is 3 to 4.5 microns (micro-meters). One micron is one-millionth of a meter. Thin fiber with low density and low thermal conductivity will promote material stability at a higher temperature. Also, thinner diameter fiber can be easier to shape due to a more vast bend radius, which is important in applications involving irregular spaces.

3. Fiber Shrinkage

A minor connection exists between doing laundry and the next relevant feature of ceramic fiber, fiber shrinkage. While doing laundry some of us choose to hang our clothes out to dry instead of using a dryer. We do so because we don’t want our clothes to shrink. The same concern exist with fibers in ceramic material. Fiber shrinkage leads to stress of the material. There is an inversely-proportional relationship between ceramic fiber shrinkage and the effectiveness of a ceramic fiber textile. In other words, the less fiber shrinkage occurs, the more effective the material. Ceramic fiber, in temperatures of 1800 degrees F for 3 hours, will experience a shrinkage of less than 3.5%

4. Working Temperature

Working temperature (operating temperature) is the temperature at which a material can maintain its physical structure while in its specified work environment. This is another feature important to the heat management characteristics of ceramic fiber textiles. Ceramic fiber must therefore have a working temperature that is very high compared to that of other non-refractory materials. For example, the working temperature of copper pipes is about 400 degrees F. Ceramic fiber has a average working temperature of about 1800 degrees F, and it can go as high as 2300 degrees F.

Hot Water

Heated Copper

5. Specific Heat

The fifth physical feature relevant to the refractory properties of ceramic fiber textiles is specific heat. Recall that the specific heat of a given material is the amount of heat required to raise it a given temperature. Various units are used to list the specific heat of a material. Water is the baseline metric for specific heat. The specific heat of water is 1 calorie per gram per degree C (equivalently it is 1 BTU per pound per degree F). In other words, it takes 1 calorie to raise 1 gram of water by 1 degree F. The specific heat of copper is 0.0923 BTU per pound per degree F. But specific heat values change as temperature changes. The specific heat of ceramic fiber is 0.27 BTU per pound per degree F at 2000 degrees F, which is considered a good specific heat value for insulation materials.

6. pH Range

Often pH is talked about when referencing a swimming pool’s chemical balance. The recommended pH level for a pool is somewhere in the range of 7.2 – 7.8. But what does this number mean? pH (potential or power of hydrogen) is a measure of how acidic or basic an aqueous solution is. The pH range goes from 0 – 14, 7 being neutral, numbers lower than 7 measuring acidity and numbers greater than 7 measuring basicity. So if pH is a range of acidity or basicity in aqueous solution why does ceramic fiber textile have a pH range from 2 – 12? The reason is ceramic fiber products are used in environments which may come in contact with harsh chemicals that carry extreme pH ranges. Ceramic fiber’s pH range of 2 – 12 states that it can withstand very acidic and basic chemicals.

To Conclude

The above listed physical features of chemical composition, fiber diameter, fiber shrinkage, working temperature, specific heat, and pH range presents an illustration of why ceramic fiber can be used in heat management applications. Ceramic fiber textiles not only offer reliable heat management characteristics, they offer versatile solutions due to the number of different textile types available. Combining this versatility with reliable heat management properties makes ceramic fiber a primary product in refractory industries.